Do you operate a vintage machine with Ferrocontrol resp. Eckelmann FCS technology, and require spares and repair services? The machine manufacturer no longer provides support? In this case, our quick repair service is exactly what you are looking for.

Your support at Eckelmann FCS (former Ferrocontrol). Welcome!

Your support at Eckelmann FCS (former Ferrocontrol). Welcome!

| Service-fcs@eckelmann.de | |

| Service hotline | +49 5221 966-200 |

| Availability | Mondays - Fridays 6:00 - 21:00 h |

| Saturdays 8:00 - 12:00 h |

Repairs Service

Wheather in providing new parts or by repairing faulty components, Eckelmann FCS's (former Ferrocontrol) repairs programme provides users with direct after-sales services for the quick repair and maintenance of old machinery.

Won't your machine manufacturer provide spare parts any longer?

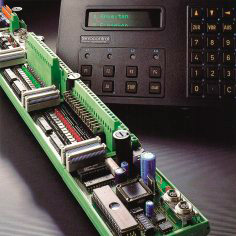

Our spares supply covers all Ferrocontrol resp. Eckelmann FCS components, ranging from servo drives and motors to fieldbus components and various industrial PCs.

|

The following table provides some examples:

| Components | Product lines |

| (Servo-)Motors | MAC, FMD, FMR |

| Servo drives Ferrocontrol | DARC-S, DARC-A, DARC-R, SVR50, TRL150, WKS |

| Servo drives lndramat | TVM, KDV, KDFS, TDM |

| Absolute encoders | WK-EN encoders/absolute shaft encoders |

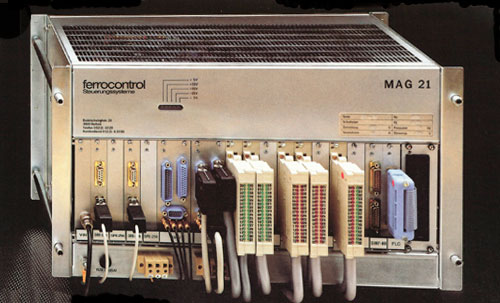

| Controller technology | Control system MAG 21, MAG 10, MAG 6, controller Z 80 |

| Fieldbus systems | ABUS fieldbus with all components such as FBSR, FBK, FBIR, FBUR |

| lndustrial PC | FIPC (various product lines) |

Which components do you require? We look forward to your inquiry.

Uncomplicated repairs

When maintenance and troubleshooting are required, our Ferrocontrol Spares & Repairs Service acts quickly in order to avoid unnecessary downtime, expenses and hassle. You can also play 100% safe and order especially critical parts for your own stockage.

|

40 years of trustworthy automation with Ferrocontrol

lf you operate a machine by one of the following manufacturers, the control cabinet will most probably contain Ferrocontrol technology:

| Furniture industry | MAW, Nottmeyer (QDB, LDB, drilling machines, fittings mounting machines), RWG, Hüllhorst (worktop saw), Meinert, Systraplan |

| Glass industry | Laser (Ladycut, Lolacut) |

| Wooden windows construction | Harbs, Gubisch (machines for wooden windows DZG) |

| Plastic windows construction | Lemuth, Haffner, FMB, RWG, ACTUAL (APH, A-400, Ecocut) |

We are familiar with all machine types. We offer both hardware and software support, and our service team is available, 6 days a week, to support you in maintaining and repairing your machines - by phone and on site.

Retrofit, or a second life for your vintage machine

On top of that, we offer retrofitting for our drive, control, and IPC technology.

Modernising our components will enhance the sustainability of your machine operations:

- more energy efficiency and productivity

- easier operation

- modern safety concepts (Functional Safety)

- increased machinery uptime

- extended machine life

The advantages of retrofitting are obvious: In many cases, the mechanics of a vintage machine are in good condition, while the electronics are no longer up-to-date. Upgrading the electronics and/or software may grant many machines a highly productive "second life".

|