Flat and sectional steel: We bring it into shape

The production of flat and sectional steel is highly demanding in terms of control technology. In order to achieve optimum end product quality in terms of dimensional accuracy and surface quality the immense rolling forces and tensile stresses (and of course many other parameters) must follow very precise target specifications. Distributed and real-time capable control systems are responsible for the follow-up control, whose performance is far above that of standard industrial systems.

Our E°ProBAS is a real-time capable automation system for demanding control engineering tasks. E°ProBAS ensures quality and performance in over 500 applications worldwide:

- Hot strip rolling mills

- Tube and section rolling lines

- Cold rolling mills

But we also offer the right solution for upstream and downstream plant components, such as casting plants, descaling machines, strip welding plants or coilers.

Smart Modernisation of Automation

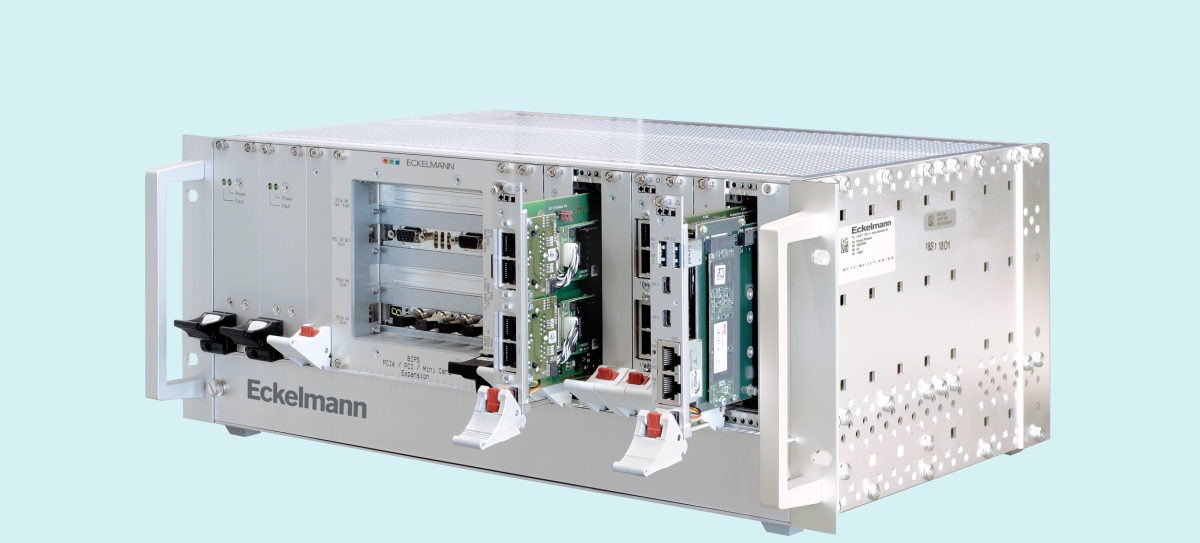

The compact PCI serial system is the most advanced controller made by Eckelmann.

Powerful box PC platform – made by Eckelmann.

Developer of the E°Probas system for more than 30 years

In-house platform for highly dynamic technical controller without limits

E°ProBAS is our own automation system, with already proven reliability in many applications, for flexible and modular automation – with over 1000 systems in the steel industry worldwide. Selected reference projects can be found in the timeline in our brochure Smart Modernisation of Automation.

- Multi-platform system

- Fast controller circuits under hard real-time conditions

- Easy upgrades without changing the application software

- Consistent system of hardware, operating system, system layer and application software

- Wide range of interface options

We make your existing plant fit and future-proof

- Improvement of the dimensional accuracy and surface quality through the most modern control technology

- Independence from proprietary hardware platforms, since FactoryWare ProBAS also runs on standard platforms such as industrial PCs and SIEMATIC S7-1500

- Improved comparability and transparency through uniform process controls and harmonized KPI monitoring

- Higher availability of machines and systems through monitoring and analysis of real-time data

- Increasing the error resistance of production processes through detailed recording and historization of process data

- Retrofits with minimum downtime using proven methods and tools, such as modeling and simulation

Scalable high-performance control